Call Us: 440-946-5300

Petroleum Industry Castings

The petroleum industry works tirelessly to supply the world's global consumption of oil, estimated at over 97 million barrels per day. Petroleum manufacturers need a partner they can rely on for the components they require to meet that demand.

With an innate understanding of the oil industry's needs, Bescast is a trusted provider of petroleum industry castings. We supply durable, corrosion-resistant industrial pump castings and other components for refining, moving and storing natural gas and petroleum products. Companies throughout the oil and gas sector depend on Bescast.

Oil Castings in the Materials You Want

We pride ourselves on being a leader in investment casting solutions for the petroleum industry. Our multi-decade expertise in oil castings allows us to deliver unmatched value and quality that will keep your operations running smoothly.

We understand the critical importance of material selection in delivering optimal performance and longevity. That's why we offer a comprehensive range of specialized materials designed to meet the rigorous demands of petroleum industry castings.

Stainless Steel

- 15-5PH: Excellent strength, ideal for high-pressure environments

- 17-4PH: Known for its remarkable durability and corrosion resistance

- 300 Series: Popular for its all-round capabilities and corrosion resistance

- 400 Series: Chosen for its superior heat resistance

Cobalt Alloys

- MM509: Perfect for high-wear conditions

- L605: Exceptional for high-temperature scenarios

- X40 (S31): Customized for high-stress applications

- WI-52: Tailor-made for environments requiring excellent corrosion resistance

Nickel Alloys (Vacuum Cast)

- HastX: For applications requiring extreme resistance to corrosion and oxidation

- IN100 to IN792: Series of nickel alloys designed for the harshest conditions — temperature, pressure and corrosive factors

- MM247, R77, R80, R125, U500: Specialty nickel alloys for the most challenging conditions in petroleum extraction and processing

Our state-of-the-art casting technology, combined with our diverse selection of materials, allows us to meet any specifications and challenges presented by our clients requiring petroleum industry castings.

Petroleum Industry Castings Applications

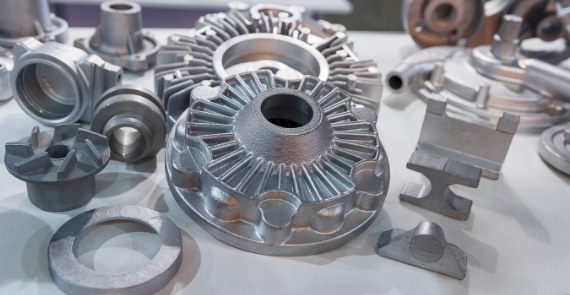

Investment casting represents the best of high-precision manufacturing, providing components that exhibit remarkable strength and offer unparalleled corrosion and wear resistance. These traits make it an ideal solution for the oil industry's challenging and demanding applications.

Investment castings can be tailored to the unique needs of the petroleum industry, such as:

- Filter screens: Critical for fluid filtration processes, high-quality filter screens are designed to withstand the erosive and corrosive environments commonly found in oil and gas applications.

- Valve components: Valve components are engineered to offer flawless operation and long-lasting durability, making them indispensable in controlling flow rates and direction in harsh conditions.

- Downhole drilling components: These components need to withstand extreme pressures and temperatures. High-performance materials and casting methods deliver products that excel in these severe conditions.

- Pump impellers: Vital for the effective circulation of fluids, pump impellers are crafted to offer optimal hydraulic efficiency while resisting wear, ensuring that your pumping systems operate at peak performance.

Why Choose Bescast for Your Petroleum Industry Castings

In the petroleum industry, where component failure is not an option, quality isn't just an added benefit — it's a necessity. That's why we've invested in securing quality certifications that set us apart in the field. Our accreditations are not just badges; they're testaments to our unyielding commitment to deliver nothing short of excellence:

- ISO 9001:2015: As an ISO 9001:2015 certified provider, we adhere to international quality management standards. This means our operations undergo rigorous external audits to consistently meet and exceed customer expectations through continual improvement.

- Heat Treat: Our heat treat certification guarantees that we have the in-house capabilities to modify our materials' physical properties to meet your specialized requirements. Through heat treatment, we can enhance durability, improve corrosion resistance and optimize performance under extreme conditions.

- NDT (non-destructive testing): Our certified non-destructive testing methods, which include radiography and penetrant techniques, allow us to meticulously inspect each component for structural integrity without causing any damage. This ensures that every product that leaves our facility meets the highest standards.

- Welding: Our welding certification serves as an assurance that our welded components can withstand the immense pressures and extreme environments commonly encountered in petroleum industry applications. Each weld is executed with unparalleled skill, ensuring maximum durability and reliability.

When you choose Bescast, you select a partner committed to quality at every level. Our extensive range of certifications is your guarantee that our petroleum industry castings meet the most stringent quality standards.

Setting Our Petroleum Industry Castings Apart

Our goal is to offer you more than just a product; we aim to provide you with solutions that bring unparalleled efficiency and reliability to your operations.

Our mastery in investment casting allows us to create parts characterized by intricate cored passageways and ultra-thin walls. Such complexities, often seen as challenges in the industry, are opportunities for us to showcase our proficiency. Our state-of-the-art technology and skilled engineers ensure that these complex structures do not compromise the integrity of your petroleum industry castings.

When it comes to tolerances, we know there is little room for error in petroleum industry castings. That's why we go the extra mile to meet — and often exceed — your design specifications. Our quality control protocols ensure that every casting we produce adheres to the closest tolerances, guaranteeing not just a fit but the perfect fit.

CURRENT PRODUCTION

Manufacturing Capacity

• 75,000 ft2 manufacturing facility

• 10,000 ft engineering and customer service

• 200+ full-time employees

Alloys Currently Poured on a Production Basis

Steel

• 15-5PH

• 17-4PH

• 300 Series

• 400 Series

Cobalt

• MM509

• L605

• X40 (S31)

• WI-52

Nickel (vacuum)

• HastX

• IN100

• IN625

• IN713

• IN718

• IN738

• IN792

• MM247

• R77

• R80

• R125

• U500

Quality Certifications

• ISO9001:2015

• AS9100 Rev D

• Nadcap

• Heat Treat

• NDT (Non-Destructive Testing) (Radiography & Penetrant)

• Welding

Approved Supplier To:

• Advanced Atomization Technologies

• Collins Aerospace

• Eaton Corporation

• GE Aviation

• Parker Hannifin

• Pratt Whitney Canada

• Prat Whitney America

• Rolls Royce N.A.

• Siemens Energy

• Solar Turbines

• Woodward

Frequently Asked Questions About Petroleum Industry Castings

As a leading investment casting company, Bescast is uniquely situated to answer your questions about petroleum industry castings. Read on for the information you need.

What Are Petroleum (Oil And Gas) Castings?

Petroleum (oil and gas) castings are used in applications for refining, moving and storing petroleum and natural gas products used by the transportation, manufacturing and energy industries.

What Types of Components Are Produced Through Petroleum Industry Castings?

Petroleum industry castings comprise a wide range of components, including pump impellers, filter screens and valve components.

Why Is Precision Important In Petroleum Industry Castings?

Precision is crucial in petroleum industry castings because the sector's harsh environments require no-fail components.

How Does the Petroleum Industry Utilize Industrial Castings?

The petroleum industry uses industrial castings to transport, refine and store oil and gas products.

Why Do Oil and Water Transfers Require High-Tech Pumps?

Oil and water transfers require high-tech pumps because these liquids often exist in environments with extreme pressures, temperatures and corrosive elements. Advanced pumps ensure efficient, reliable movement of these fluids while minimizing wear, maintenance and operational costs.

Rely On Bescast for Petroleum Industry Castings

Don't settle for less when it comes to the critical components your petroleum operations depend on. Choose Bescast — where unparalleled quality, cutting-edge technology, and rigorous certifications come together to take your performance to new heights. Act now and see how Bescast can make a difference in your petroleum industry castings.