Call Us: 440-946-5300

BLOG

What's the Difference Between Casting and Forging? A Comprehensive Comparison Guide

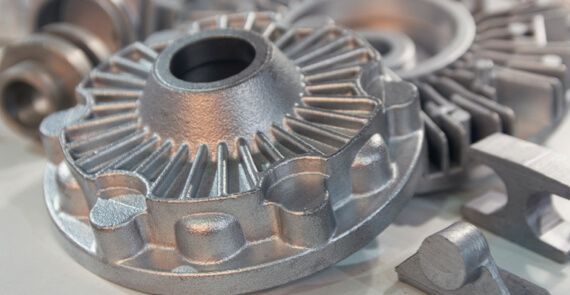

Casting and forging are two of the most widely used methods for shaping metal, each playing a vital role in modern manufacturing. Whether producing parts for aerospace, energy, or industrial machinery, choosing the right process can affect everything from performance to production costs. While both approaches shape raw materials into functional components, how they do it and what they can achieve vary significantly.

Understanding the difference between casting and forging is essential for selecting the right fit for your project. In this guide, we'll walk through how each process works, where each one shines, and why that distinction matters for precision, complexity, and overall efficiency.

Table of Contents

Overview of Metal Forming Processes

Metal forming is the foundation of countless components across critical industries, from turbine blades and valve bodies to structural supports and high-performance housings. Among the many techniques used to shape metal, casting and forging are two of the most established and effective. Each method brings its own strengths to the table and serves a different set of design and performance goals.

Forging vs. Casting

At a basic level, casting involves pouring molten metal into a mold, allowing it to cool and solidify into a specific shape. In contrast, forging uses compressive force to reshape solid metal, creating a component that's mechanically tough and structurally sound. These approaches might aim for the same end result, a finished part, but the processes and outputs can differ dramatically.

Knowing the difference between casting and forging is key to choosing the right manufacturing route. Whether you're designing a part that requires intricate detail or one that must withstand heavy loads, the decision has direct implications for quality, performance, and cost-efficiency.

The Casting Manufacturing Process

In the casting manufacturing process, metal is heated until it's molten and then is poured into a mold, where it cools and subsequently solidifies into the desired shape. This method is especially effective for creating components with complex geometries, internal cavities, and precise dimensional requirements. It's a process built for flexibility, offering wide design freedom that would be difficult, if not impossible, to achieve through mechanical shaping alone.

High-Precision Results

Among the many casting methods, investment casting stands out for its ability to deliver high-precision results.

Investment casting can produce near-net-shape components with minimal machining and is often used for:

Investment casting delivers reduced material waste and tighter tolerances across intricate features in these and other applications.

Numerous Materials

Investment casting supports castings in numerous materials, including:

It's especially useful when the application demands fine detail, thin walls, or smooth surface finishes.

Trade-Offs

Of course, like any method, casting has trade-offs. Longer lead times for mold creation and potential for internal porosity are two examples. That said, when parts demand complexity, high-temperature resistance, or performance-critical precision, casting, especially investment casting, offers clear advantages.

The Forging Manufacturing Process

Forging uses compressive force to shape solid metal into a desired form. Instead of melting the material like in casting, forging keeps the metal in a solid state and applies intense pressure through dies or hammers. The result is a part with exceptional strength, high impact resistance, and improved grain flow alignment, which enhances structural integrity.

Various Types

There are several types of forging, including:

- Open-die

- Closed-die

- Impression-die

Each is suited to different part sizes and complexity levels. Closed-die forging, for example, is common for producing high-strength components with repeatable shapes, while open-die forging is better suited for larger, less complex geometries.

Heavy Loads or High Stress

The forging manufacturing process is often chosen for parts that must perform under heavy loads or high stress, like crankshafts, gears, and axles. It's especially useful when the application demands resistance to fatigue and impact.

Various Materials

The forging of metals typically involves alloys such as:

- Alloy steel

- Stainless steel

- Carbon steel

Non-ferrous metals like aluminum and titanium are also used, depending on performance requirements.

Trade-Offs

As with casting, there are trade-offs to consider. Forging can struggle with producing complex internal features and tight tolerances, and may require extensive machining after the fact. It also limits material use flexibility compared to casting methods like investment casting.

Casting vs Forging: A Side-by-Side Comparison

When evaluating the difference between casting and forging, it's not a question of which process is better; it's about which one better fits your part's performance, complexity, and cost requirements. Here's how the two compare across core manufacturing criteria:

1. Precision and Complexity

Casting, particularly investment casting, is ideal for components with intricate geometries, thin walls, or complex internal structures. The mold-driven nature of the casting manufacturing process allows for near-net-shape parts that minimize post-processing. In contrast, forging is more limited in design complexity and often requires additional machining to achieve tight tolerances.

2. Strength and Structural Integrity

Forged parts are typically stronger due to the realignment of the metal's grain structure during deformation. This gives forging of metals an edge in load-bearing applications or environments with high-impact stress. However, modern casting alloys and thermal treatment options can still meet demanding performance standards, especially where precision is prioritized over brute strength.

3. Cost and Tooling

Forging often has higher upfront tooling costs and requires more powerful equipment, but it can become cost-effective at scale, especially for simple shapes. Casting, meanwhile, tends to be more economical for low-to-medium production volumes and for parts that would be costly to machine from forged stock. The choice here often hinges on the size of the production run and the part's design.

4. Lead Time and Turnaround

For simpler geometries, forging can offer quicker turnaround once tooling is in place. However, casting, especially investment casting, can reduce lead times by minimizing machining steps and allowing faster iteration of complex designs using techniques like wax patterning.

5. Material Flexibility

Casting accommodates a broader range of alloys, including those difficult to form or forge. If your design requires specialty materials with high corrosion resistance, temperature tolerance, or unique mechanical properties, casting can offer more options.

From casting and forging differences in part precision to variability in mechanical properties and cost implications, the choice between the two can be complex.

When to Choose Casting Over Forging

For parts that demand tight tolerances, intricate features, and complex geometries, casting, and particularly investment casting, offers a clear technical advantage. When a design includes internal cavities, undercuts, or fine surface details, the casting manufacturing process enables shapes that forging simply can't match without extensive secondary operations.

Minimal Material Waste

Casting is also an excellent fit when minimizing material waste is a priority. Because parts are formed near net shape, there's less excess to machine away, which can be especially valuable when working with high-cost alloys. This makes casting a strong choice for industries like aerospace, medical, and energy, where precision and material efficiency matter.

Cost and Production Volume

The advantages and disadvantages of investment casting become especially relevant when evaluating cost and production volume. While mold creation does take time, investment casting becomes increasingly efficient for medium-to-high part complexity. It also opens up a broader selection of materials, including nickel-based alloys, offering greater flexibility for engineers working with specialized performance requirements.

If your project calls for complex design, dimensional accuracy, or material versatility, casting delivers where forging reaches its limits.

When Forging Is the Better Fit

While casting excels in complexity and precision, there are many situations where forging is the preferred choice, especially when performance under pressure is non-negotiable. The forging manufacturing process produces parts with excellent structural integrity, thanks to the grain flow alignment that occurs during deformation. This results in higher tensile strength, better fatigue resistance, and outstanding durability.

Repetitive Stress

For applications involving repetitive stress, high-impact loads, or extreme mechanical demands, forging of metals offers reliability that's hard to beat. Automotive components like crankshafts, suspension arms, and gears often rely on forged parts for this reason. The same goes for heavy machinery where mechanical strength and toughness are non-negotiable.

Strength Benefits vs. Design Limitations

When evaluating the advantages and disadvantages of forging, engineers often weigh its strength benefits against its design limitations. While complex features may require additional machining, the tradeoff is justified when structural performance takes priority. Forging is also well-suited for high-volume production runs of simpler parts, where tooling investments pay off quickly and repeatability is key.

If your project prioritizes durability, impact resistance, and long service life, especially in straightforward geometries, forging delivers consistent results you can count on.

Turn to Bescast for Your Investment Casting Needs

Now that you know the difference between casting and forging, you're ready for the next step. If your project demands precision, complexity, and material efficiency, investment casting delivers where other methods fall short. At Bescast, we specialize in helping manufacturers turn demanding specs into high-performance cast components with accuracy and repeatability. Ready to talk through your next project? Contact Bescast to learn how our investment casting expertise can help you get it right from the start.

Frequently Asked Questions About Forging vs. Casting

As a leading voice in the $17.8 billion global investment casting market, Bescast fields numerous questions about forging vs. casting. Here are some common things people want to know.

Are there size or weight limitations for casting or forging?

Yes. Casting allows for a wide range of part sizes, including very large or intricately shaped components, but extremely heavy castings may require specialized handling. Forging, on the other hand, is better suited for parts within certain size and weight limits due to equipment and tooling constraints.

How do modern techniques like investment casting and closed-die forging compare?

Investment casting excels at producing complex, high-precision components with minimal finishing work, making it ideal for intricate designs. Closed-die forging offers excellent strength and dimensional consistency but is generally better suited to simpler geometries due to tooling limitations.

Between a casting and forging of the same component, which will be stronger?

In most cases, a forged component will be stronger because the grain structure is realigned during deformation, enhancing mechanical properties. However, a cast component can still meet rigorous performance standards, especially when using advanced alloys and heat treatment techniques.

Related Articles

CATEGORY

RECENT POSTS